Pressure Vessel And Reactor

Pressure vessel & reactor

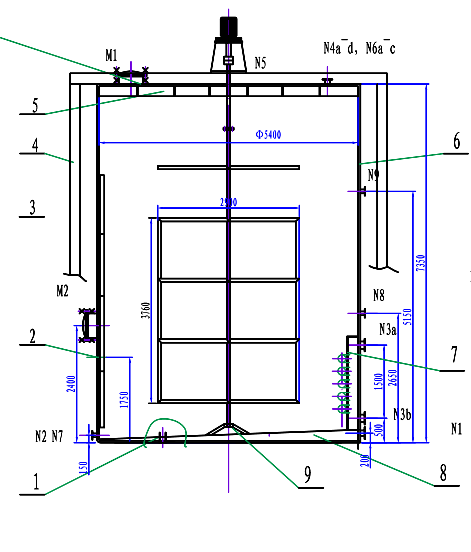

FRP reactor and agitator tank are composed of motor, decelerator, FRP tank, FRP cover, agitator paddle, sealing device, etc.

Volume range: 0.5 ~ 500 cubic meters.

Inner diameter range: DN600 ~ DN8000mm.

Pressure class: -0.1Mpa~1.0Mpa.

Temperature:-40℃~150℃

Flange standard: All kinds of standards can be selected according to the customer's requirements.

Mixing paddle and shaft: Paddle type, anchor type, frame type, screw type etc.

Agitator tank: Made of fiberglass (vinyl natural resin, fiberglass or carbon fiber).

Motor accessories: Adopt motor and speed reducer from well-known manufacturers, or specify by the user.

Shape: Vertical (flat bottom, slope bottom, round bottom, cone bottom, etc.), horizontal.

Appearance: Translucent. Special requirements for example to add gel coat or color paste to change surface color.

Saddle: It is selected according to user's requirement. The material is carbon steel (FRP corrosion resistance for inner liner) or stainless steel, etc.

Heat exchanger: Stainless steel coils (S304,316L,2205, etc.) and graphene coils can be selected.

Seal: Water seal and mechanical seal.

Advantages: Small thermal expansion coefficient, low thermal variation coefficient, because of the same material, different from thermal expansion between two materials in composite reactor (metal and rubber lining, glass lining, enamel), it can solve the problem of cracking or falling off due to the sudden cold and heat of the medium, and extend the service life.

Please contact tc@fygrp.com for more details

![[pics:title]](/static/upload/image/20200921/1600694177869483.jpg)

![[pics:title]](/static/upload/image/20200921/1600694177648979.jpg)

![[pics:title]](/static/upload/image/20200921/1600694177497793.jpg)

![[pics:title]](/static/upload/image/20200921/1600694178922558.jpg)

![[pics:title]](/static/upload/image/20201009/1602231865131964.jpg)